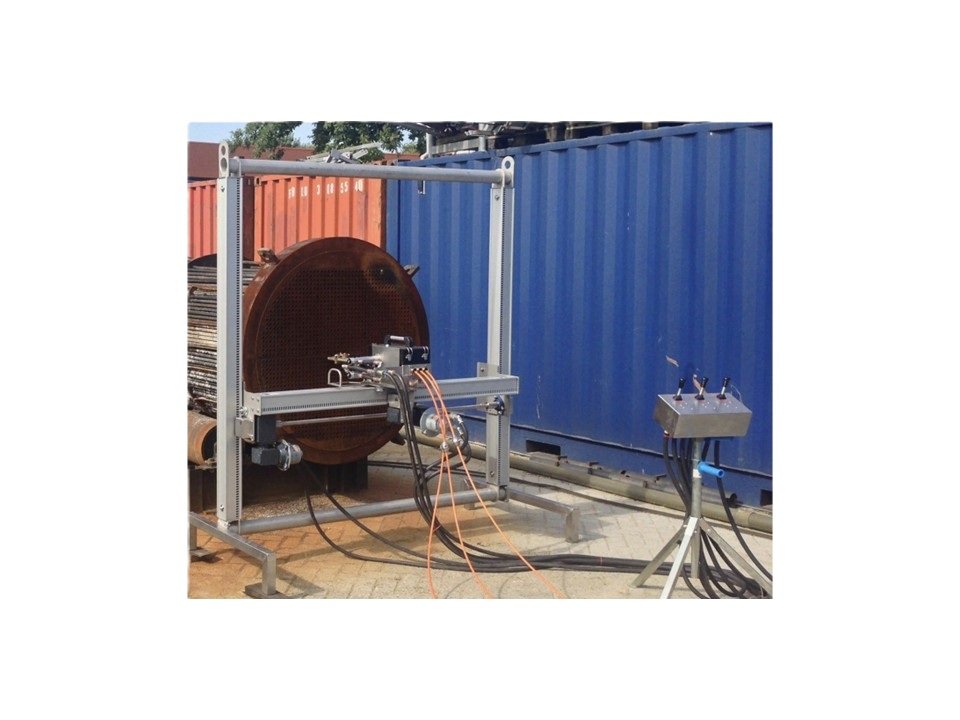

Automated Lancing Machine

Product Description

Our Automated Lancing Machines are purpose-built for safe, efficient, and precise lancing operations in the oil & gas, petrochemical, refinery, and power generation sectors. Designed to replace manual lancing, these machines improve operator safety, enhance cleaning efficiency, and ensure consistent results in demanding industrial environments.

We offer both 3-lance and 5-lance pneumatic-operated models, giving clients the flexibility to choose the right solution depending on process requirements and site conditions.

Key Features & Advantages:

- Automated Pneumatic Operation: Eliminates manual effort, ensuring smooth, controlled, and reliable lancing.

- Multiple Lance Configurations (3-lance & 5-lance): Allows simultaneous lancing of multiple tubes for faster cleaning and reduced downtime.

- Compact & Rigid Design: Engineered to perform in restricted spaces while maintaining structural strength and long service life.

- Enhanced Safety: Reduces direct operator involvement in high-risk zones, minimizing exposure to heat, pressure, and contaminants.

- High Productivity: Capable of handling large-scale tube cleaning tasks quickly, improving turnaround efficiency in shutdowns and maintenance cycles.

- Customizable Options: Machines can be tailored with different lance lengths, nozzles, and operational controls as per client requirements.

Applications:

- Heat exchanger tube cleaning

- Waste heat boiler lancing

- Petrochemical reactor and furnace maintenance

- Refineries, power plants, and offshore facilities

By integrating pneumatic-driven automated lancing machines into maintenance programs, operators achieve greater efficiency, reduced downtime, and improved workplace safety, making them a cost-effective solution for high-performance industrial cleaning.

Interested in this product?

Contact us for more information, pricing, or to request a quote.

Contact Us